Pin-on-Disk Wear Testing

Ducom Wear and Friction Monitor (Pin on Disc Tester) records friction and wear in sliding contact in dry, lubricated, controlled environment and vacuum conditions. It has become the industry standard in wear and friction analysis.

Pin-on-Disk wear testing is a method of characterizing the coefficient of friction, frictional force, and rate of wear between two materials. During this tribological test, a stationary disk articulates against a rotating pin while under a constant applied load.

Mass-loss evaluation and differential analysis of test fluids are typically performed post-test to characterize wear properties. In addition, a contact profilometer can be utilized to evaluate the changes in surface topography due to articulation. Metallurgical evaluation of the post-test wear scarring can also be performed.

Application

- Fundamental wear studies, wear mapping and PV diagrams

- Testing of metals, ceramics, soft and hard coatings, plastics, polymers, composites

- Lubricants and cutting fluids

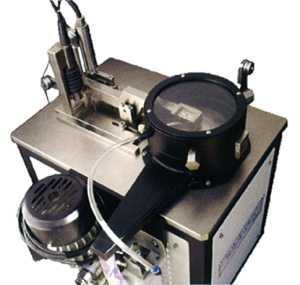

Four Ball Tester

Ducom’s four ball tester is designed to determine wear preventive (WP), extreme pressure (EP), frictional, fatigue and shear stability behavior of lubricants.

The four ball testers is designed with instrumentation which permits measurement of actual load, RPM and temperature. Frictional torque during the test is measured. All these parameters are displayed during the test and data is acquired and displayed graphically on-line. Duration of the test is set by a digital preset timer. The scar diameter is measured with a measuring microscope. An optional scar measuring microscope with image sensor permits acquiring of scar image on PC. It is possible to measure the size of the scar on PC screen with a variety of cursors.

In wear preventive tests average scar diameter on the surface of stationery balls is reported. It is the measure of wear preventive property of lubricant.

In extreme pressure test the load is increased in specified steps after every run of the spindle till the load is arrived at which the lubrication at the contact fails resulting in welding of the balls. This load, at which welding occurs is the index of extreme pressure property of the lubricant.

In fatigue test under IP 300/82 can be performed with the Ducom four ball tester. The three lower balls are allowed to roll in a ball-cup with ground ball race. Rolling contact fatigue failure is indicated by increase in vibration which indicates end of the test.

Features

The pin-on-disk method of wear characterization is beneficial across numerous industries, including:

- Characterization of wear between bearing surfaces for the medical device industry (hip, knee, shoulder, ankle, spine); Excellent option for comparing and understanding material characteristics prior to longer term medical implant wear testing.

- Piston ring, cam bearings, and brake pad wear simulation for the automotive industry

- Hard metal coating and film integrity testing for the aerospace and manufacturing industries

- Analysis of the reduction in wear based on fluid variations for oil and lubricant manufacturers

Features

- CE Marked

- EP and WP test in 1 machine

- Computer controlled operation

- Facility to document test results

- Comparative viewing of test results

- CCD Image Acquisition System

- Modular electronics for ease in servicing

- Ergonomically designed for comfortable use

- Inbuilt storage for Accessories, Tools and Samples

- Safety interlocks for the safety of both users and machine

- Quick onsite recalibration

- Retractable wheels for easy relocati

Specification

Specimen pin size diameter : 3, 6, 8, 10 and 12mm. 20-30mm long

Wear disc size diameter : 165 x 8mm | 50-100mm (reciprocatory)

Disc rotation : min 200 rpm, max 2000 rpm | Min 1 rpm,max 100 rpm (recipocatory)

Load : min 5N to max 200N.

Wear : 0 micrometer, Max-2000 micrometer

Stroke Length : 60mm only for recipocatory

Specification

Speed : Min 300 rpm, Max 3000 rpm

Max axial load : 10000N

Temperature : Amnient to 100°C

Test ball diameter : 12.7mm

Scar diameter : 0.01 to 4mm